How deep is the marking with a dot marker?

Dot marking is a frequently used manner to place an indelible marking in hard materials. Our Sales Engineers are regularly asked the question: How deep is the marking with a dot marker? Frank Van Dyck, Sales Engineer at Automator, addresses this question.

Depth of dot marking

How deep the marking, also called the engraving, is, is a frequently asked question. “Especially if the object is still being processed after the marking, for instance painted or galvanised, then the depth of the marking is important. The marking must then be deep enough so that it can still be read properly after the processing,” as Frank explains the question.

“The many different materials on which a dot marker can be used implies that one specific maximum depth for a marking cannot be indicated. We always test in practice what the dot marker does on the specific object, in order not to be confronted with surprises later.”

What does the depth depend on?

You can read in the specifications of the supplier that the maximum hardness of the material can be 65 HRC. “It is not possible to indicate an expected depth based on the hardness of the material alone,” explains Frank. “The angle of the needle point, the coarseness of the component, the required quality (think about thickness, size) of the letters, the stroke, and the type of device also play a role.”

As already indicated, it is also important if the object still needs to be processed after the marking. And if so, what type of processing. “Of course you do not want it to turn out afterwards that the marking can no longer (sufficiently) be read after the processing. Only a test on a representative sample ensures the correct marking solution with the necessary depth of the marking.”

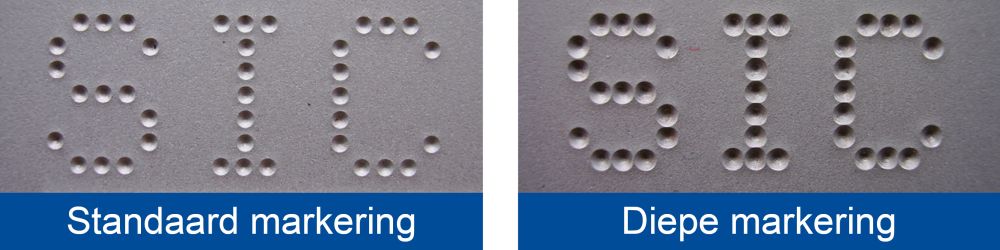

Dot markers for deep marking

If a dot marker is already being used in the production and if the marking is, for any reason whatsoever, no longer satisfactory then this does not imply that a dot marker cannot do the job.

“The dot marker is available in various editions. For instance, a standard edition, one that is suitable to make more than 100 markings a day, and an edition specifically developed for deep marking. The latter has a thicker needle and a heavier stroke in order to mark deeper”, clarifies Frank. “It could therefore well be that with a different edition the required depth can be accomplished. It becomes a bit monotonous, but I cannot say anything other than that in practice only testing can give the answer.”

Want to know more?

Curious if dot marking fits in your production process? Then have a look together with one of our Sales Engineers. You can reach them by calling +31 (0)10 415 64 00 or by sending an email to info@automator.nl.

Do you prefer reading a bit more about dot marking first? You can find more information on the page Dot Marking.

Go to the page Dot Marking