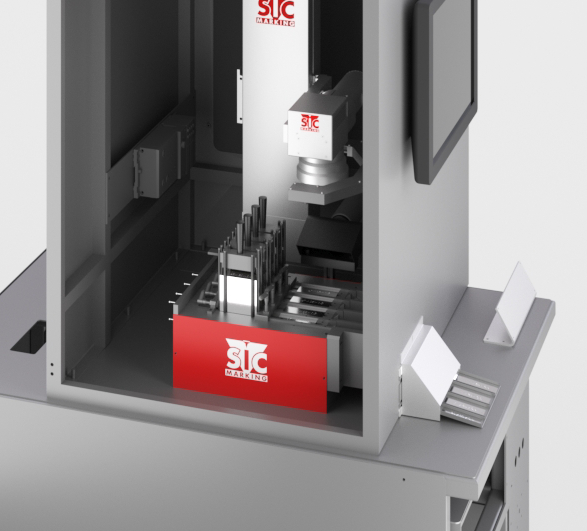

Lasers are increasingly used for coding, engraving and marking of materials and products. Depending on the material or product that needs to be marked and the required speed, a specific type of laser with the appropriate power is needed for the marking task. The marking does not fade or bleed and can consist of anything: numbers, logos, data matrix codes; the possibilities are endless. You can choose between a standalone laser marking station, integrable laser or an mobile laser.

Laser coding is one of the most reliable methods for coding, marking and engraving. The lasers require relatively little maintenance and are subject to much less downtime than other kinds of coding apparatus.

Because laser marking and coding is suitable for so many different materials and speeds, there are also various benefits per application. The benefits that apply to almost all applications are:

There are more benefits per application.

Discover the benefits of laser coding yourself!

We would be happy to take a look with you at the opportunities for laser coding in your production environment. Call us on +31 (0)10 415 64 00 or email us at info@automator.nl.

Everything about laser marking bundled together

Everything about laser marking bundled togetherThere's a lot to say about marking with a laser. For example, about the marking; how it is done and its unique properties. You can read more about it in Sic Markings online brochure Laser marking.

You will also find included the features, capabilities and options of both the laser marking station and the integrable laser in the brochure.

Would you rather some personal advice?

Prefer to discuss the possibilities with one of our Sales Engineers? That’s possible!

Call +31 (0)10 415 64 00 or send an email to info@automator.nl.

Reading tip: Also read one of our blogs:

4 x 'true or false' statements about marking with a laser

Is laser marking on plastic really that difficult?

Then get in touch on working days between 8 a.m. and 5 p.m. using the details below for immediate advice.

+31 (0)10 415 64 00

info@automator.nl

Automator

Breevaartstraat 37

3044 AG Rotterdam