Labeling is more than ‘putting on a sticker’

.jpg?width=200&height=200) There are several reasons for attaching a label to a product. For instance, the label might contain product information and a use by date. The label might also play a part in the area of traceability. But what exactly do you have to look for when buying a labeler? You can read more about this in this blog with an explanation by our Sales Engineer and product specialist in the field of labelling, Remco Krosenbrink.

There are several reasons for attaching a label to a product. For instance, the label might contain product information and a use by date. The label might also play a part in the area of traceability. But what exactly do you have to look for when buying a labeler? You can read more about this in this blog with an explanation by our Sales Engineer and product specialist in the field of labelling, Remco Krosenbrink.

Remco Krosenbrink has worked for many years in the packing sector and he has seen quite a few packing lines. But he still doesn’t find working in this sector at all boring. “In my field you can honestly say: everyone wants something different. Attaching a label on a product is more than just putting on a sticker. There are many factors to take into account when choosing the right labeler. To mention just a few: How flexible does the line have to be, how fast do the products pass through the line and how much space is there to install a labeler?”, explains Remco.

The criteria for the choice

Of course, in any situation there are often specific criteria that play a part in the choice of the right labeler. A few criteria that play a part in many cases should be mentioned. We have listed them for you below and then we explain them one by one:.jpg?width=200&height=200)

- the label itself

- flexibility

- ease of use

- speed

- space

- future requirements

The label itself

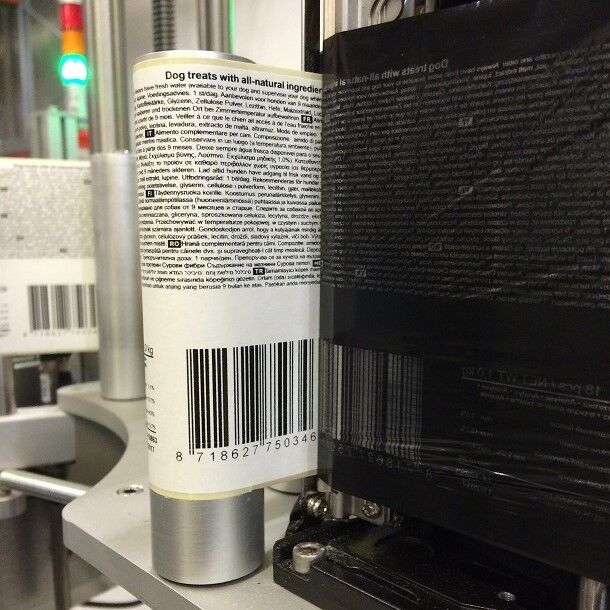

It probably sounds obvious. But it will astonish you how often in practice everything is considered, but careful determination of the right label receives close attention. Remco says: “It’s a good idea to think seriously about what kind of label has to be attached. Is the label already printed or does it still have to be printed? What label format fits on the product? And does all the information fit on it? Take into account information that is already on the product itself, making sure that the information remains legible and does not disappear under the label. Does the product have one or more places where a label must be attached? And there are even more questions to consider. In short, look critically at what kind of label or labels are required.”

Speed

Another obvious point, but also definitely important to consider properly. At what speed do the products have to be labelled? You always want to avoid the labeler being the bottleneck in the production process because it can’t keep up with the speed of production.

Flexibility

What level of flexibility is required of the labeler? So you have to think about the difference between the attachment of printed labels and labels that have to be printed in real time before attachment. In the latter case, there must always be a printer on the labeller. If various products have to be labelled by the same labeler, this will probably have consequences for the format of the label. The labeler will then have to be able to attach various label formats. And don’t forget: Is the labeler located on a fixed line or must it be moveable?

Remco stresses: “Because there are so many different labelers, there are also many options. Make sure that the labeler meets the requirements imposed on it within your production process.”

Ease of use

A user-friendly labeler is of course preferred. How easy the labeler must be to operate also depends on the people who operate it. Must everyone be able to do it or only people trained for it? If the labeler is remotely operated, there are often different requirements than if the labeler is set up on the spot.

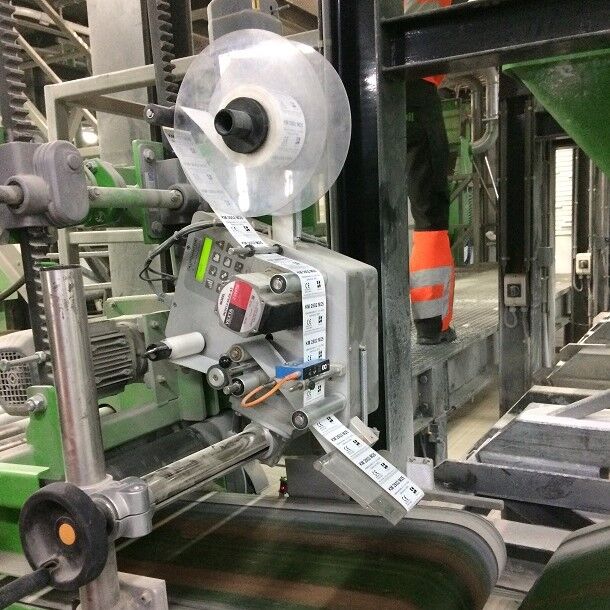

Space.jpg?width=200&height=200) The amount of space available for the labeler within the production process determines to a large extent how the labeler can be positioned. Is there room to fit a control screen by the labeler or does it have to be remotely operated? Is there a fixed place to install the labeler or does another solution have to be found?

The amount of space available for the labeler within the production process determines to a large extent how the labeler can be positioned. Is there room to fit a control screen by the labeler or does it have to be remotely operated? Is there a fixed place to install the labeler or does another solution have to be found?

Future requirements

Remco explains the last point: “When a labeler is to be purchased, a wishlist is produced based on the criteria we have listed above, among other things. Right now is already a good time to think about the future. Are changes expected within the not-too-distant future regarding production volume or anything similar? Then it may be worthwhile considering right now whether the labeler that is the right choice now will also still be the right choice in the new situation. This can save a lot of expense if the new situation arises.”

Great variety of solutionsSo many different issues regarding labelers call for different solutions. In one case, a standard labeler is the solution. In another case, thanks to customisation the labeler perfectly suits the requirements that the production process imposes on it. Remco explains the customisation options: “Within Automator we have been working for years with EME in the area of (customised) labeling systems. Thanks to the variety of solutions that we have been able to develop for our clients, we are very familiar with all the possibilities. We are in fact prompted to produce an appropriate solution by a challenging labeler issue. And in recent years we have definitely demonstrated that we are capable of a great deal,” says Remco lastly with a wink. He continues in earnest: “EME continues to develop its labelers, in particular by responding to the questions coming from the workfloor. For instance, nowadays you can control several labelers with one touchscreen. And the number of connection cables has been considerably reduced so as to minimise the chance of squashing cables and to take a great step forward in the area of hygiene.”

EME

Because our customised solutions often come about in collaboration with EME, we will explain to you below the benefits that the latest generation of EME labelers offer you:

- A user-friendly touchscreen. With this you can control several labelers if desired. There is an option to switch this on or off for each labeler.

- The labelers offer various functions that can be adapted in a flexible manner.

- Ease of use. With several labelers, they can be operated via one touchscreen. Remote operation is also available as an option.

- Space-saving.

- Easy to understand. You can see all the functions of several labeling systems on one screen.

Do you need help with choosing the right labeler solution?

If you need help with choosing the right labeler solution, with Remco or one of his colleagues you’ve come to the right place. You benefit from their expertise built up over many years. Ring +31 (0)10 415 64 00 without obligation or send an email to info@automator.nl.