Printing on laminated boxes, the do's and don’ts.

A lot of (outer) packaging is made of porous material, such as cardboard. Printing on this type of packaging is relatively easy. Since the material to be printed on is porous, the ink can easily soak into the substrate, resulting in a good print. But what if you have packaging made of non-porous material, such as laminated cardboard or film? How do you get a nice print on that with a printer?

We put the question to Remco Krosenbrink, Sales Engineer at Automator, and active in the industry for years.

Printing on non-porous material

What issues do you encounter when you want to print on non-porous materials?

“If you use a standard water- or oil-based ink, the ink drips down immediately after printing. This is because the ink cannot soak into the material,” Remco explains.

Is there a solution that allows you to print directly on a non-porous substrate?

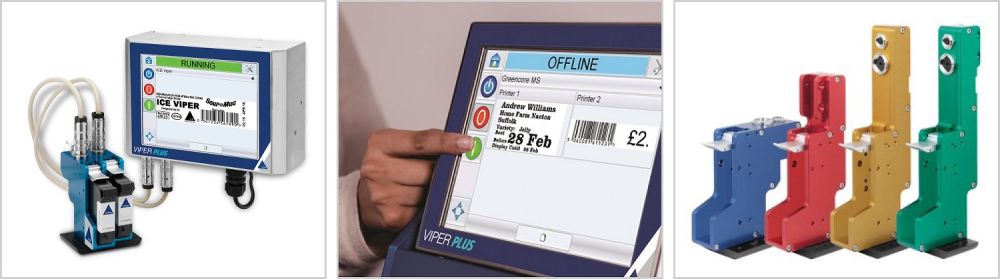

“Yes indeed,” responds Remco, “At Automator, for example, we have the Viper inkjet printer in our range, which prints well on laminated material or film. However, you must choose the right type of ink suitable for printing on non-porous materials.”

“Furthermore, you have to consider the speed at which the product passes the printer and the distance from the product to the print head,” Remco adds. “But these criteria come into play with any printing solution.”

The drawbacks of ink

Printing directly on non-porous material is possible, provided you pair the printer with the correct type of ink. In general, using ink has a few drawbacks. For instance, it can stain or dry out if not used correctly, making it unusable. Does the ink suitable for printing on non-porous materials have any other drawbacks compared to standard inks?

“No, apart from being more expensive than water- and oil-based inks, as an operator, you won't notice any difference using it,” answers Remco.

Alternative to printing

Besides putting information directly onto the packaging, you can print the information on a label and place the label onto the packaging. The advantage of this is that you don't have to buy a costlier, special ink. “However, there are also drawbacks to using a label. Apart from using extra material, sometimes, it simply looks better to print the information directly onto the packaging. And the eye deserves something, too!” says Remco with a smile.

Advantages and disadvantages of the printer

The Viper inkjet printer is bound to have advantages and disadvantages.

“Close attention was paid to uptime and ease of use while designing the Viper. This is reflected, among other things, in the lack of wear parts that need to be periodically replaced and the ease with which the cartridge can be replaced within 15 seconds,” Remco briefly explains about the printer's advantages.

“If the print needs to be higher than 51 mm, you cannot use the Viper. It's also not the best printer for barcode printing,” Remco explains about its disadvantages.

Did you know?

The Viper printer, like the Zodiac, Torus and Vulcan printing systems, is part of the ICE range of printing solutions. ICE is known for its high-quality solutions characterised by ease of use, minimal maintenance requirements, and, therefore, a high uptime. Furthermore, the compact Viper printer is virtually odour-free, and there is much less chance of a dirty floor.